Operating the Grain Elevators

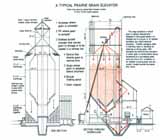

When the grain has reached the pit the elevator option selects a bin—either an empty one or one containing grain of the same grade as that being delivered. By turning a large wheel near the platform he can adjust the delivery spout at the top of the elevator and direct grain into any one of the bins in the elevator. Having selected a bin and adjusted the spout, he starts up the endless belt, in the elevator “leg,” which lifts the grain to cups attached to the belt, up to the top of the elevator. There it is dumped into the proper bin through the distributor.

When enough grain has been received to fill one or more boxcars, and there is a need at the terminal and transfer elevators for that type of grain, the boxcars are allocated to the elevator and delivered alongside it on a railway spur. When a car is ready, the bottom of the bin is opened and the grain falls into a hopper on a scale. There it is weighed to determine the number of bushels being sent out. From the hopper, the grain is dropped onto the pit where it is picked up and sent back up to a small distribution bin at the top of the elevator by the cups of the endless belt. The distribution bin is connected to the loading spout and the grain falls through this into the boxcar. When the car is full, its doors are closed and sealed. It usually takes 4 hours to prepare and load a boxcar. The load is recorded with the company and the railway, and a passing train collects the car and takes it to a terminal elevator, or occasionally, to a mill elevator.

Canada, Department of Agriculture, Ottawa, Publication 467, 1972, p. 5.